The Single Strategy To Use For Roar Solutions

( Zone 0, 1, or 2). This variant will also affect the resourcing requirements for job preparation. Once Whole lots are defined, you can develop tasting plans based on the example size of each Great deal, which refers to the variety of random equipment products to be inspected. To determine the called for example size, 2 elements need to be reviewed: the size of the Lot and the category of inspection, which suggests the degree of effort that must be applied( minimized, normal, or enhanced )to the examination of the Great deal. By incorporating the category of assessment with the Whole lot size, you can after that establish the suitable being rejected standards for a sample, indicating the allowed number of malfunctioning things found within that sample. For even more information on this procedure, please refer to the Power Institute Standards. The IEC 60079 common recommends that the maximum interval between examinations should not surpass three years. EEHA examinations will likewise be carried out beyond RBI campaigns as component of scheduled maintenance and equipment overhauls or repair work. These assessments can be attributed towards the RBI example dimensions within the influenced Whole lots. EEHA inspections are conducted to determine faults in electrical devices. A heavy racking up system is essential, as a single tool may have multiple mistakes, each with varying degrees of ignition danger. If the mixed score of both inspections is much less than two times the mistake score, the Lot is deemed appropriate. If the Great deal is still thought about unacceptable, it must undertake a complete assessment or reason, which may set off stricter examination methods. Accepted Great deal: The root causes of any kind of mistakes are determined. If a typical failing mode is found, additional tools may need maintenance. Mistakes are categorized by intensity( Security, Honesty, Home cleaning ), making sure that urgent concerns are examined and dealt with without delay to minimize any effect on security or procedures. The EEHA database need to track and tape-record the lifecycle of mistakes together with the rehabilitative actions taken. Implementing a robust Risk-Based Examination( RBI )method is vital for guaranteeing conformity and safety in handling Electric Devices in Hazardous Locations( EEHA). Automated Fault Rating and Lifecycle Management: Easily manage mistakes and track their lifecycle to boost examination accuracy. The intro of this support for risk-based examination additionally reinforces Inspectivity's position as a best-in-class option for governing compliance, in addition to for any kind of asset-centric assessment usage case. If you have an interest in finding out much more, we invite you to ask for a demo and uncover just how our solution can transform your EEHA administration processes.

With over one decade of mixed Ex lover experience (IECEx/ATEX, EEHA), Saipex began to advertise the value of skills of all workers associated with the Hazardous Location field in 2019. In 2021, our partnership with IndEx and Tech Ability International (TSI) marked a milestone in the Saipex roadway to continue Ex renovation.

The Best Guide To Roar Solutions

In regards to eruptive risk, a hazardous location is a setting in which an explosive ambience exists (or may be anticipated to be existing) in quantities that need unique precautions for the building, installment and use devices. In this write-up we explore the difficulties dealt with in the office, the risk control steps, and the needed expertises to work safely.

These compounds can, in particular conditions, form explosive environments and these can have significant and terrible repercussions. Most of us are acquainted with the fire triangular get rid of any kind of one of the 3 aspects and the fire can not take place, but what does this mean in the context of harmful areas?

This is after that verified via assessment and screening and is protected throughout the life of the index installment by employing the proper maintenance strategies, supplemented by regular inspection. When all these measures are taken, they should likewise be recorded. The verification dossier consists of information such as the dangerous location category illustration, manufacturers' documents, equipment accreditation, layout illustrations and calculations, evaluation documents, and documents of a person's competency and continuing specialist growth (CPD), such as via ECA's eCOMS software application.

Roar Solutions Can Be Fun For Anyone

It is crucial that students comprehend and have a comprehensive knowledge regarding just what makes up a harmful location. The student should also understand why training is essential prior to attempting to tackle work or specifying devices right into a dangerous area. These areas are also called classified locations and are defined as areas which have a high possibility of an explosion due to the possible existence of flammable gases, vapors, dusts etc.

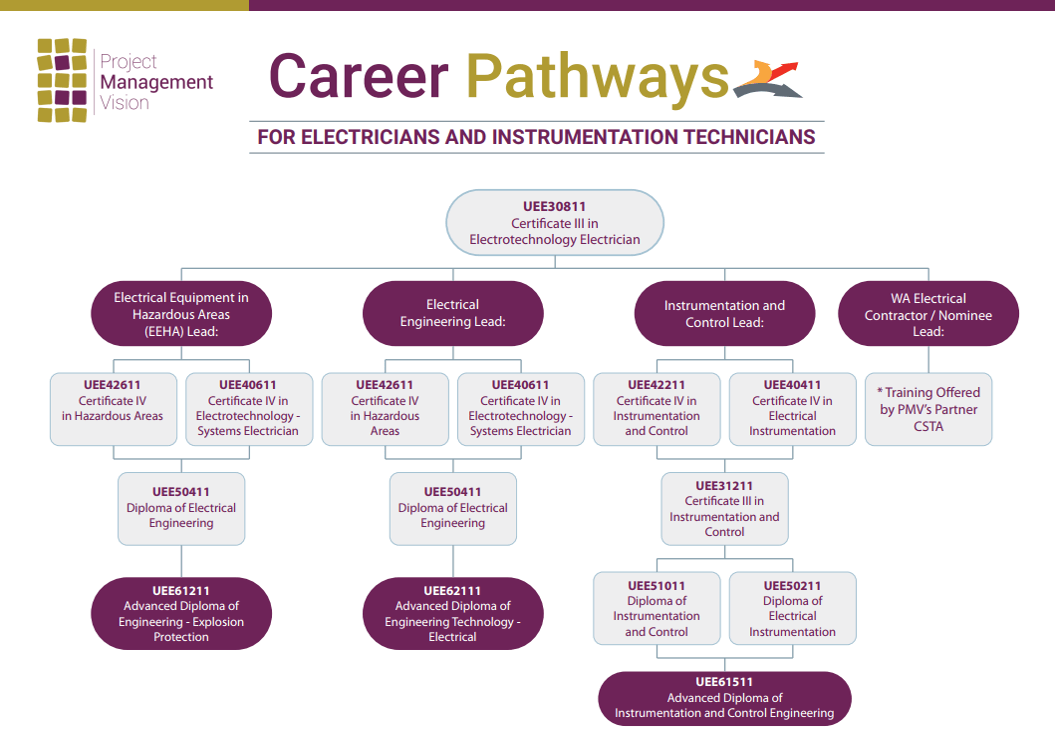

Industries which contain unsafe areas are now demanding that electrical employees that are defining or functioning in these locations need to have an unsafe location qualification that deems them qualified. Jobs in these markets are extremely satisfying so you need to be prepared. To meet this demand for the sector, across the country acknowledged training in Certificate IV in Harmful area Electrical and EEHA training on the development of experienced professionals.

The Single Strategy To Use For Roar Solutions

Tech Skills Australia is a Registered Training Organization offering you with the most budget friendly and quickest method obtaining your qualification - high voltage courses. Our teachers are sector qualified and have several years of process experience. Our courses have actually aided numerous individuals from company supervisors to day-to-day staff members in getting a strong hold on this not so difficult however high threat training

The training additionally consists of determining the dangerous locations, sources of explosion and the homes of dangerous products in addition to the responsibilities and features of all events, laws, systems, criteria and method codes connected to hazardous locations. We offer instrumentation and harmful area solutions that remain in compliance to latest AS/NZS and global market standards.

Comments on “Some Known Details About Roar Solutions”